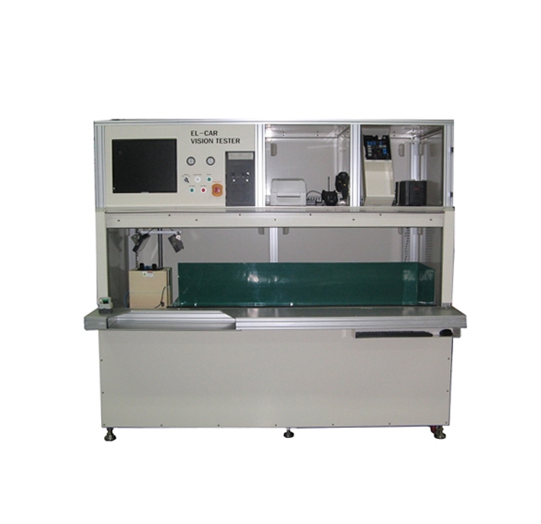

In manufacturing process of fuse box, it detects badness of fuse and relay insertion using camera and blocks an outflow of badness. And it supplements problems of the existing naked eyes inspection and produces good products only.

Specification

1. Inspection object

- Fuse and Relay

2. Inspection items

- Fuse : wrong position, missed, turned position

- Relay : wrong position, missed

3. Inspection method

- Fuse is judged to be different kinds from colors of body, and relay is judged to be different kinds

from colors and with/without letters

- Without loading products on a certain location, Vision revises products partly.

- After inspection, if good ones, prints labels and attach labels to products.

And if bad ones, makes alarm works and workers recognize, and then re-inserts parts and re-inspects.

- For good ones, saves data such as model no., inspection date, count and etc.

- For bad ones, displays a location of badness on monitor to make it easy to compare with the existing

good ones images and makes workers recognize easily what parts should be inserted.

- Lighting : Strobe method