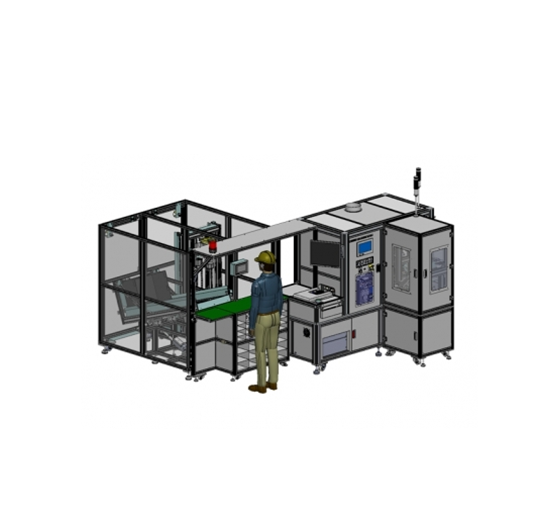

Equipment that automatically performs QR Marking and Paper Label on the case by temporarily fixing the PCB board to the case in the junction box production line and press-fitting it.

Specification

- Assembly target: car junction box

- Assembly items: Temporary assembly → PCB board, junction box case, MBS

Automatic assembly → Case & MBS Press, QR marking, label automatic folding and insertion

- Assembly speed: 8Sec/1Set

- Equipment components: . Product Loading Lifter (2 sets)

. Assembly table and work instruction table (inspection information can be linked to MES)

. Cases and MBS coverage

. QR-mark Laser Etching Unit (can be checked by attaching a label, Option)

. Paper label automatic folding machine and inserting device

. Unloading Pick and Place and Feeding Conveyor

Machine Features

- Possible to recognize model through barcode and build data base

- Inspection result transmission and defect classification, application of MES (inspection data storage and history management)

- Customization possible for each customer, configuration change possible through consultation according to assembly model change

- Rapid response and A/S → remote control, operation of dedicated personnel